Now, without further ado:

Skip to 2:10 to just see it moving already

Awesome, right!? :D

I've been home for winter break, weary from the end of my fifth semester at MIT (I managed to maintain a 4.5 GPA!), and staying up in the odd hours of the night and relaxing... by working on TinyArm.

Before I went home for winter break, I decided to drop by MITERS to pick up TinyArm, among other things. I hadn't really worked on it since the beginning of the school year, where the last breakthrough was getting it to move around using hard-coded step waypoints in the firmware. I tried for many, many nights to get "zee USB" working... to no avail.

Now that I was home, I decided to do a few things. I wanted to model TinyArm, to figure out its dimensions and true limits before I started working out the kinematics/inverse kinematics. I also wanted the model because I wanted to test out the Solidworks-To-URDF Exporter (Now that I had a 64-bit computer). I also wanted to finally get my computer talking to the control board, even if it meant not using the USB protocol directly.

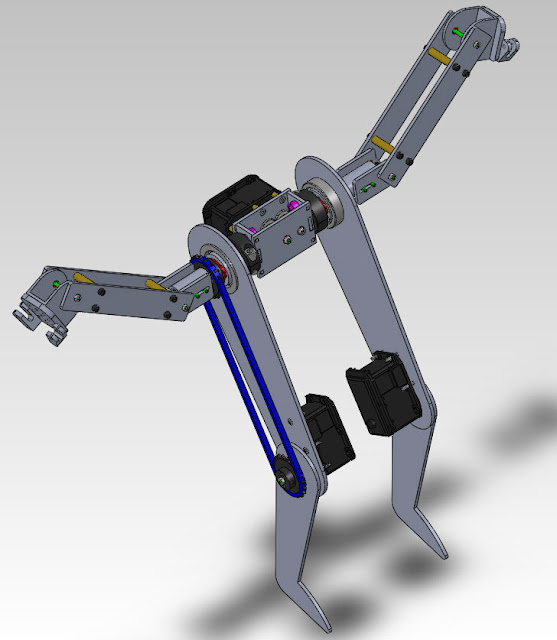

I first grabbed my trusty calipers and began modelling the manipulator in Solidworks from scratch. Luckily, every single dimension on the thing is a proper Imperial value. Some lengths were 8.0 inches, some were 2.5, some were 6.375, but they all had some very nice number. Here you can see the final model I made.

And here's a closeup. The most important dimensions are there, though I may eventually add the cables, gearing, and motors. The gripper even closes the way it's supposed to!

Too bad the URDF exporter never worked. Even with only the base links and the shoulder link selected, it was not able to identify the points or axes for each joint. Oh well, I may just make myself a custom URDF anyway.

Next, I decided to start getting my board talking. After another few minutes screwing around with USB (At some point this semester I once managed to get the board to show up as a USB device on my computer... once. ) I decided to switch to Serial.

I looked into using serial USART communication, and found out the two pins I routed for D+ and D- in USB are the same as RX and TX for one of the serial ports built into the atxmega16a4u chip on TinyArmTroller.

So I cut a USB 2.0-B cable and made an adapter for a Sparkfun FTDI Basic Breakout Board I had lying around. Good thing my dad had soldering equipment at home!

With this setup, and with the help of some example code I found online (which actually exists, UNLIKE F***ING USB) I was able to get it listening and talking! A few more hours of coding and I could send it six step (FROM MY COMPUTER!!) values as a waypoint (OVER SOME WIRES! :D).

I then took some time to re-calculate my estimated mapping of Angle to Steps, by moving each DOF to ~0 degrees, then to ~90 degrees, and seeing what step values took me there. Turns out, these numbers were very clean ones. For example, for the shoulder joint, -500 steps was 90 degrees, and -1400 steps was 0 degrees, leading the angle-to-step conversion to be :

(theta-140)*10 = #steps

Vid again:

Now, what does the future hold for my wonderful TinyArm? I need to solve the inverse kinematics, meaning I need to solve for some functions that will tell me "what angles do I need to command in order to get to a certain X,Y,Z,theta?". With that, I can place some blocks in stacks in front of it and have it rearrange them, or something.

I can make it grab a pencil and start moving along the ground plane, tracking my mouse movements. When I click, the robot moves the pencil down, and I can write things with the arm.

I can attach it to TurtleBot and use it as a manipulator arm to go get me sodas or something, because it could pick up upwards of 2 lbs. (4 lbs according to the Microbot website...)

I can attach it to the underside of a quadrotor...

See you next post!